In today's metal processing market, it is known that the production efficiency of fiber laser cutting machines is very high. The cutting speed of the fiber laser cutting machine is proportional to the power size, the cutting speed can reach 30m/min, the thickness can reach 70mm, the excellent cutting speed and the great cutting thickness make the laser cutting machine widely used in the industry.

Fiber laser cutting machine industry is undergoing transformation and upgrading, in the current broad industry prospects, fiber laser cutting machine must strive to develop new technologies in order to occupy a place in the increasingly fierce market competition and rapid growth of the market, in response to future production demand, fiber laser cutting machine can be developed in these directions:

1.high automation production efficiency

At present, the cost of metal processing is mainly in labor and raw materials, upgrading automated production can effectively reduce labor costs, improve production efficiency, in the future, automated production is the mainstream.

2. Functional diversity

The same device with different functions can easily expand its range of use. In order to realize the multi-function of the same equipment, it is necessary to adopt modular design and multi-module combination design to achieve new equipment suitable for different materials and processes.

3. Joint production line

A product line is destined to be implemented by multiple devices, and integrating functions into one device will cause inconvenience in operation and maintenance. Several units of comparable efficiency are combined to form a complete production line.

4. Introduction of new technology

At present, the fiber laser cutting machine is still the use of semi-automatic or fully automatic production methods, with the continuous development of information technology, advanced fiber laser cutting machine will have higher precision, higher efficiency, more humane program, so that the fiber laser cutting machine is more automatic and intelligent.

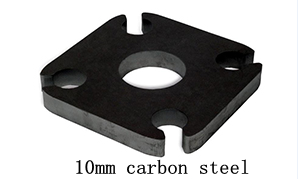

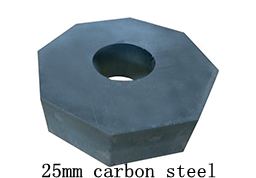

Carbon steel cutting technology demonstration