I、The principle, characteristics and application of laser cutting

1. Principle of laser cutting

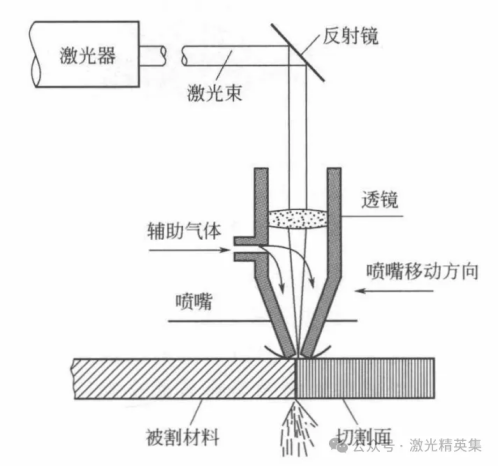

Laser cutting is the use of a focused high-power density laser beam to scan the surface of the workpiece, in a very short time to locally heat the material to thousands to tens of thousands of degrees Celsius, so that the irradiated material quickly melted, vaporized, ablated or reached the ignition point, and at the same time with the beam coaxial high-speed airflow to blow off the molten material, the workpiece cut, to achieve the purpose of cutting materials. If there is a thermal reaction between the blown gas and the material to be cut, this reaction will provide additional energy required for cutting; The airflow also cools the cutting surface, reduces the heat affected zone and ensures that the focusing mirror is not contaminated. Laser cutting is a thermal cutting process. The principle of laser cutting is shown in the following figure.

Whether cutting is done with a CO2 laser or a Nd:YAG laser, the principle is basically the same. In practical applications, the laser cutting head is equipped with a lens, which can focus the laser to a small focus (spot), the power density at the focus is extremely high, and the focus is adjusted to the surface of the workpiece to melt or vaporize the cut material. The laser cutting area is shown below.

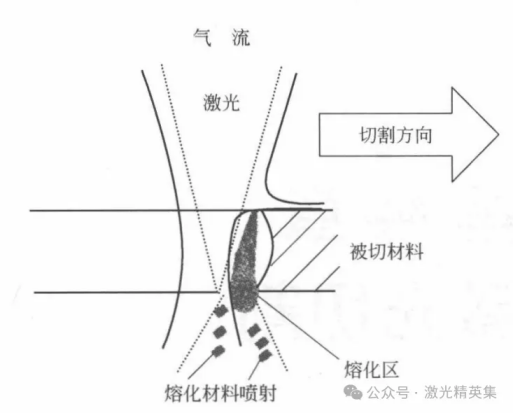

The laser cutting process occurs on the surface at the end of the incision, called the ablation front. The laser energy is partly absorbed by the ablation front, and partly reflected through or through the ablation front to the incision space. The ablative front is heated, melted, or vaporized by absorbed laser light and exothermic reactions during cutting, and blown away by airflow. Some of the heat is transferred to the base material by thermal conduction, or by radiation loss, and is carried away by the air stream by convective heat transfer.

An important factor of laser cutting is the absorption of human laser at the ablation front of the workpiece incision, which is the basis of effective laser cutting. The absorption of the laser is determined by the polarization, mode and convergence Angle of the laser, and also by the shape and inclination of the ablation front, as well as the properties of the material and the degree of oxidation.

Laser cutting uses a high-energy laser to melt or vaporize the material at the incision site, and blows it away with high-speed auxiliary airflow to complete the cutting. The power density of laser cutting can reach 10^4~10^5W/cm2. The laser source is generally a CO2 laser beam with a working power of 500~2500W. This level of power is lower than that required by many household electric heaters, but the laser is concentrated in a small area through lenses and mirrors. The high concentration of energy enables rapid local heating to vaporize the material. In addition, because the energy is very concentrated, only a small amount of heat is transmitted to the rest of the material, resulting in little or no deformation. The use of laser can be very accurate to cut complex shape of the bad material, the cut bad material need not be further processed.

Although a high energy CO2 laser can cut a carbon steel plate with a thickness of 25mm, the thickness of the plate should generally not be greater than 10mm if you want to obtain a high-quality incision.

2. Classification of laser cutting

Laser cutting may use auxiliary gases to help remove melted or vaporized materials, or may not use auxiliary gases. According to the different auxiliary gases used, laser cutting can be divided into four categories: vaporization cutting, melting cutting, oxidation melting cutting and controlled fracture cutting.

(1) Vaporization cutting

The use of a laser beam with high energy density to heat the workpiece, so that the surface temperature of the material rises rapidly, and the boiling point of the material is reached in a very short time, enough to avoid melting caused by heat conduction, the material begins to vaporize, and some of the material vaporizes into vapor and disappears. At the same time, part of the material as ejecta is blown away from the bottom of the slit by the auxiliary gas flow, forming a notch on the material. In the process of vaporization cutting, the vapor carries away the melting particles and erodes the debris, forming holes. In the vaporization process, about 40% of the material disappears as steam, and 60% of the material is removed by the air stream in the form of droplets. The heat of vaporization of the material is generally large, so the laser vaporization cutting requires a large power and power density. Some materials that cannot be melted, such as wood, carbon materials and certain plastics, are cut and shaped by this method. Laser vaporization cutting is mostly used for cutting extremely thin metal materials and non-metallic materials (such as paper, cloth, wood, plastic and rubber, etc.).

(2) melting cutting

The metal material is melted by laser beam heating. When the power density of the incident laser beam exceeds a certain value, the interior of the material where the beam irradiation begins to evaporate and form a hole. Once formed, the hole absorbs all the incoming beam energy as a black body. The hole is surrounded by a molten metal wall, and then through a nozzle coaxial with the beam of non-oxidizing gas (Ar, He, N, etc.), relying on the strong pressure of the gas to discharge the liquid metal around the hole, as the workpiece moves, the hole moves horizontally in the cutting direction to form a incision. The laser beam continues to shine along the leading edge of the incision, and the molten material is continuously or pulsatively blown away from the incision. Laser melting cutting does not require the metal to be completely vaporized, and the energy required is only 1/10 of that of vaporized cutting. Laser melting cutting is mainly used for the cutting of some non-oxidizing materials or active metals, such as stainless steel, titanium, aluminum and its alloys.

(3) oxidation aid cutting

The principle is similar to oxygen-acetylene cutting. It uses a laser as a preheating heat source, and uses oxygen or other active gases as a cutting gas. On the one hand, the blown gas reacts with the cutting metal and releases a lot of oxidation heat; On the other hand, the molten oxide and melt are blown out of the reaction zone, forming a notch in the metal. Due to the oxidation reaction in the cutting process generates a lot of heat, so the energy required for laser oxygen cutting is only 1/2 of the melting cutting, and the cutting speed is much greater than the laser vaporization cutting and melting cutting.

The basic principle of oxidation-aided cutting is as follows:

1)Use oxygen or other active gases. The surface of the material is quickly heated to the ignition temperature under the irradiation of the laser beam, and a fierce combustion reaction occurs with oxygen, and a lot of heat is released. Under the action of this heat, a small hole filled with steam is formed inside the material, and the hole is surrounded by a molten metal wall.

2)The combustion material is transferred into slag to control the combustion rate of oxygen and metal, and the higher the oxygen flow rate, the faster the combustion chemical reaction and the removal of slag. The oxygen flow rate is not the higher the better, because too fast a flow rate will lead to a rapid cooling of the reaction product (that is, metal oxide) at the slit exit, which is not good for the cutting quality.

3)There are two heat sources in the process of oxidation assistance-cutting, namely, laser irradiation energy and the heat energy generated by the chemical reaction of oxygen and metal. When cutting steel, the heat released by the oxidation reaction accounts for about 60% of the total energy required for cutting. Compared with the inert gas, the use of oxygen as the auxiliary gas can obtain a higher cutting speed.

4) In the process of oxidation aid cutting with two heat sources, if the burning speed of oxygen is higher than the moving speed of the laser beam. The slit was wide and rough; If the laser beam moves faster than the burning speed of oxygen, the resulting narrow slit and smooth laser oxidation melting cutting is mainly used for cutting steel, is the most widely used cutting method.

(4) Control fracture cutting

For brittle materials that are easily damaged by heat, a laser beam with high energy density is used to scan the surface of the brittle material so that the material is heated to evaporate out of a small slot, and then a certain pressure is applied, and the laser beam is heated for high-speed and controllable cutting, and the brittle material will split along the small slot. The principle of this cutting process is that the laser beam heats a local area of the brittle material, causing a large thermal gradient and serious mechanical deformation in the area, resulting in the formation of cracks in the material. As long as a balanced heating gradient is maintained, the laser beam can guide the crack to create and expand in any desired direction.

Controlled fracture uses the steep temperature distribution generated by laser grooving to create local thermal stress in the brittle material to break the material along the small grooves. It should be noted that this controlled fracture cutting is not suitable for cutting acute angles and corner slits. Cutting large closed shapes is also not easy to succeed. The control fracture cutting speed is fast and does not require too much power, otherwise it will cause the workpiece surface to melt and destroy the slit edge. The main control parameters are laser power and spot size.