The principle, characteristics and application of laser cutting

3. Characteristics of laser cutting

Laser cutting technology has obvious advantages compared with other thermal cutting methods, and is generally characterized by fast cutting speed and high quality. Its specific characteristics can be summarized as follows:

Because the laser spot is small, the energy density is high, and the cutting speed is fast, the laser cutting can obtain better cutting quality. The laser cutting incision is narrow, and the dimensional accuracy of the cutting parts can reach up to 0.05mm. The cutting surface is clean and beautiful, the surface roughness is only tens of microns (generally Ra is 12.5~25um), and even laser cutting can be used as the last process, and the slit can be welded without reprocessing, and the parts can be used directly. After the material is laser cut, the width of the heat affected zone is small, the performance of the material near the cutting is almost unaffected, and the workpiece deformation is small, the cutting precision is high, the geometry of the slit is good, and the cross-section shape of the slit is more regular rectangular.

The comparison of laser cutting, oxygen-acetylene cutting and plasma cutting methods is shown in Table 41. The cutting material is 6.2mm thick mild steel plate.

(2) High cutting efficiency

Due to the transmission characteristics of the laser, the laser cutting machine is generally equipped with multiple numerical control tables, and the entire cutting process can be fully CNC. When operating, just change the numerical control program, it can be applied to the cutting of different shape parts, both two-dimensional cutting and three-dimensional cutting can be achieved.

(3) Fast cutting speed

Cutting 2mm thick mild steel plate with laser power of 1.2kW, cutting speed up to 600cm/min; Cutting 5mm thick polypropylene resin plate, cutting speed up to 1200cm/min. With a 2kW laser cutting 8mm thick carbon steel plate, cutting speed is 1.6m/min, cutting 2mm thick stainless steel plate cutting speed is 3.5m/min, heat affected zone is small, deformation is minimal. The material does not need to be fixed in the laser cutting, which can save the fixture and save the auxiliary time of loading and unloading.

(4) Clean, safe and pollution-free

There is no contact between the torch and the workpiece during laser cutting, and there is no tool wear. Processing parts of different shapes, do not need to replace the "tool", just change the output parameters of the laser. The laser cutting process has low noise, low vibration and no pollution, which greatly improves the working conditions of the operator.

(5) There are many types of cutting materials

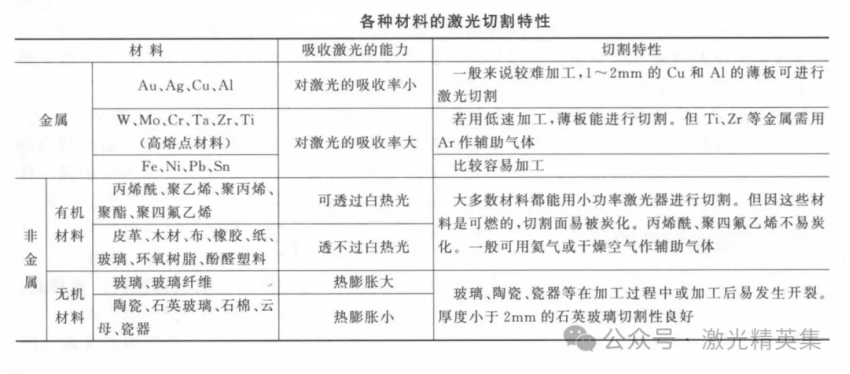

Compared with oxy-acetylene cutting and plasma cutting, there are many types of laser cutting materials, including metal, non-metal, metal base and non-metal base composite materials, leather, wood and fiber. Different materials, due to their own thermal physical properties and different absorption rate of laser, show different laser cutting adaptability. Using CO2 laser, the laser cutting characteristics of various materials are shown in the following table.

The shortage of laser cutting is due to the limitations of laser power and equipment volume, can only cut plates and pipes of medium and small thickness, and with the increase of workpiece thickness, the cutting speed decreases significantly. Laser cutting equipment costs high, one-time investment is large.

In terms of cutting accuracy and incision surface roughness, CO2 laser cutting does not exceed electric machining; In terms of cutting thickness, it is difficult to reach the level of flame and plasma cutting. However, the above significant advantages are enough to prove that CO2 laser cutting has been and is replacing a part of the traditional cutting methods, especially the cutting of various non-metallic materials. It is an advanced processing method that develops rapidly and is used more and more widely.