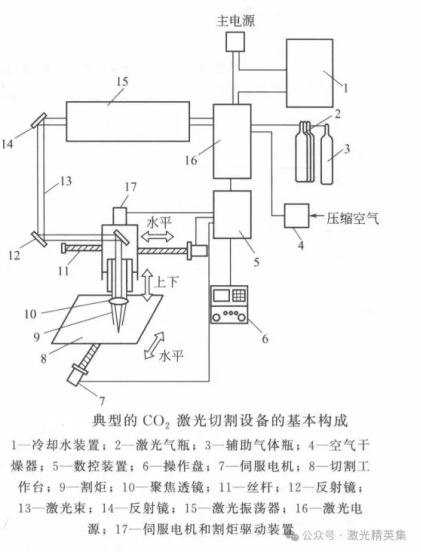

Laser Cutting Equipment Composition

1. Components and working principle of laser cutting machine

Laser cutting machine is composed of laser emitter, cutting head, beam transmission component, machine table, numerical control system, computer (hardware, software), cooler, protective gas cylinder, dust removal machine, air dryer and other components.

1) Laser generator laser light source device. For the use of laser cutting, in addition to a few occasions to use YAG solid-state lasers, most of the use of electro-optical conversion efficiency is high and can output high power CO2 gas lasers. Because laser cutting requires high beam quality, not all lasers can be used for cutting.

2) The cutting head mainly includes nozzle, focusing lens and focusing tracking system and other parts. The cutting head driving device is used to drive the cutting head to move along the Z axis according to the program, and is composed of servo motor and transmission parts such as screw or gear. (1) Nozzles: There are three main forms of nozzles: parallel, collected and cone forms. (2) Focusing lens: using the energy of the laser beam to cut, the original beam emitted by the laser must be focused through the lens to form a high energy density spot. Medium telephoto lenses are suitable for thick plate cutting, and the spacing stability of the tracking system is required to be low. The short focus lens is only suitable for thin plate cutting below D3, and the short focus has strict requirements for the spacing stability of the tracking system, but its output power requirements for the laser can be greatly reduced. (3) Tracking system: laser cutting machine focus tracking system is generally composed of focus cutting head and tracking sensor system. The cutting head consists of light focusing, water cooling, air blowing and mechanical adjustment parts. The sensor is composed of sensing element and amplifying control part. According to the different sensing elements of the tracking system is also completely different, here, there are two main forms of tracking system, one is a capacitive sensor tracking system, also known as non-contact tracking system. The other is the inductive sensor tracking system, also known as the contact tracking system.

3) The beam transmission component external light path: refraction mirror, used to guide the laser in the required direction. In order that the beam path does not fail, all mirrors should be protected by a protective cover, and a clean positive pressure protective gas is passed into the lens to protect it from contamination. A good lens will focus a beam of light with no divergence Angle into an infinitesimal spot. A 5.0-inch focal length lens is generally used. 7.5-inch lenses are only used for >12mm thick materials.

4) Machine tool table machine tool host part: laser cutting machine tool part, to achieve X, Y, Z axis of the movement of the mechanical part, including cutting platform.

5) CNC system CNC system control machine tool to achieve X, Y, Z axis movement, but also control the output power of the laser.

6) Cooling system chiller: used to cool laser generator. Laser is the use of electrical energy into light energy device, such as CO2 gas laser conversion rate is generally 20%, the remaining energy is converted into heat. The cooling water carries away the excess heat to keep the laser generator working normally. The chiller also cools the external optical mirror and focusing mirror of the machine tool to ensure stable beam transmission quality and effectively prevent the lens from becoming deformed or bursting due to excessive temperature.

7) The gas cylinder includes the laser cutting machine working medium gas cylinder and auxiliary gas cylinder, used to supplement the laser shock of industrial gas and supply cutting head with auxiliary gas.

8) Dust removal system extraction of dust and dust generated during processing, and filtration treatment, so that exhaust gas emissions in line with environmental protection standards.

9) Air cooling dryer and filter are used to supply clean dry air to the laser generator and beam path to keep the path and mirror working normally.