The principle, characteristics and application of laser cutting

5. Laser cutting of different metal materials

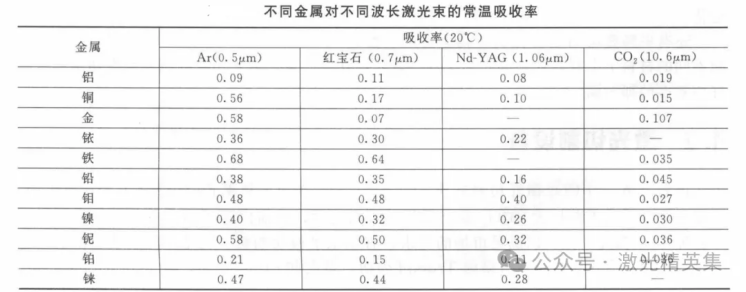

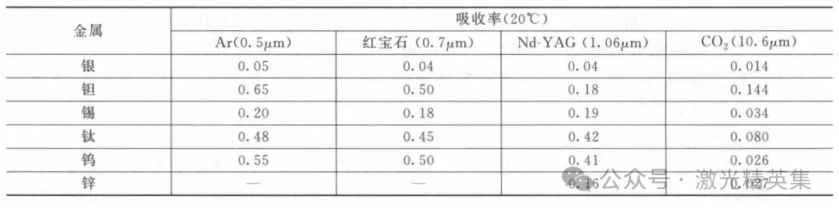

Laser cutting of metal materials Although almost all metal materials have a high reflectivity of infrared wave energy at room temperature, CO2 lasers emitting beams in the far infrared band (10.6um) have been successfully applied to laser cutting of many metals. The metal material has poor absorption of 10.6um laser beam, and the initial absorption rate is only 0.5% to 10%. The absorption rate of most metals in the molten state rises sharply, generally increasing by 60% to 80%.

① Carbon steel. The thickness of the laser cutting carbon steel plate can reach 25mm, and the slit of the carbon steel plate can be controlled within a satisfactory width range by using the oxidation melting cutting machine, and the slit of the thin plate can be narrow to about 0.1mm.

② Alloy steel. Most alloy structural steels and alloy tool steels can be used to obtain good edge cutting quality by laser cutting. When oxygen is used as a processing gas, the cutting edge is slightly oxidized. For sheets up to 4mm thick, nitrogen can be used as a processing gas for high pressure cutting. In this case, the cut edge will not be oxidized. For plates with a thickness of more than 10mm, the laser uses a special plate and can get better results by oiling the surface of the workpiece during processing. For high strength steel, as long as the process parameters are properly controlled, it is also possible to obtain a straight cut edge without sticking slag. However, for high-speed tool steel and hot forging die steel containing tungsten, corrosion and slime phenomena are easy to occur during laser cutting.

③ Stainless steel. For the stainless steel sheet based manufacturing industry, laser cutting is an effective processing method. In the case of strict control of laser cutting heat transfusion, the width of the heat affected zone can be limited, thus ensuring good corrosion resistance of stainless steel. Oxygen can be used if the edge oxidation does not matter, and nitrogen can be used to obtain an oxidization-free burr edge, which does not require further treatment. Applying a layer of oil film on the surface of the plate will get a better perforation effect without reducing the processing quality.

④ Aluminum and its alloys. The laser cutting of aluminum and its alloys is a melting cutting mechanism, and the auxiliary gas used is mainly used to blow away the molten product from the cutting zone, usually to obtain a better notch quality. For some aluminum alloys, attention should be paid to preventing the occurrence of intergranular micro-cracks on the slit surface. Although aluminum alloys have high reflectivity and good thermal conductivity, the laser cutting method can still be used to cut aluminum with a thickness of less than 6mm, depending on the alloy type and laser power. When oxygen is used, the cutting surface is rough and hard; When using nitrogen, the cutting surface is smooth. Pure aluminum is very difficult to cut, and can only be cut if there is a "reflection absorption" device installed on the system, otherwise the reflection will destroy the optical components.

⑤ Copper and its alloys. Pure copper (copper) because of the high reflectivity, basically can not be cut with CO2 laser beam, cutting brass (copper alloy) should use a higher laser power, auxiliary gas using air or oxygen, can be cut on the thinner plate. Both pure copper and brass have high reflectivity and very good thermal conductivity. Brass plates with a thickness of less than 1mm can be cut with nitrogen; The thickness of the copper plate below 2mm can be cut, and the processing gas must use oxygen. Pure copper and brass can only be cut if a "reflection absorption" device is installed on the system, otherwise the reflection will destroy the optical components.

⑥ Titanium and its alloys. Pure titanium can well couple the heat energy converted by the focused laser beam, and the chemical reaction is severe when the auxiliary gas uses oxygen, and the cutting speed is fast, but it is easy to generate an oxide layer at the cutting edge, and may also cause overburning. The use of air as an auxiliary gas can ensure the cutting quality. The titanium alloy laser cutting quality commonly used in the aircraft manufacturing industry is better, although there will be a little sticky slag at the bottom of the slit, but it is easy to remove. Titanium sheets are cut with xenon and nitrogen as processing gases.

⑦ Nickel-based alloy. Also known as superalloys, there are many varieties, most of which can be implemented by laser oxidation aid cutting.

The incision quality is good. The use of laser cutting equipment can cut less than 4mm stainless steel plate, adding oxygen in the laser beam can cut 25mm thick carbon steel plate, but after oxygenated cutting will form a thin oxide film on the cutting surface. The maximum thickness of laser cutting can reach 30mm, but the size error of the cutting parts is large.

The absorption rate of the material to the laser beam plays an important role in the initial stage of heating. Once the small hole is formed inside the workpiece, the black body effect of the small hole makes the absorption rate of the material to the beam close to 100%. In laser cutting practice, the effect of the surface state of the material on the absorption rate of the beam can be used to improve the cutting performance of the material, such as coating the absorbing material layer on the aluminum surface, which can significantly improve the cutting speed.