After the epidemic era, with the trend of intelligent manufacturing, the rapid development of the laser industry, laser technology and laser products are also becoming more mature. Laser processing subvert the traditional processing methods, help enterprises to transform and upgrade, intelligent manufacturing accelerate. The traditional pipe processing method has many steps, need to saw, milling, punching, drilling, etc., compared with the laser pipe cutting, laser pipe cutting only needs a piece of equipment and an operator, greatly enhance the efficiency, reduce costs, and form a competitive differentiation.

Comparison of laser tube cutting with traditional tube processing

Laser tube cutting is widely used in various industries, continuous innovation and breakthroughs in tube splicing process, can realize riveting, round tube coherent line, square tube bending lap, bevel cutting lap and other processes.

1 Riveting

Can realize round tube and round tube riveting, square tube and square tube riveting, square tube and round tube riveting and so on.

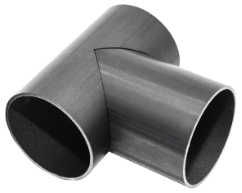

2 Round tube coherent line

Round tube coherent line cutting, mostly used in electric cars, bicycles and other industries for tube cutting.

3 Square Tube Bending Lap

Square tube can be programmed to achieve V, R-port cutting, bending, can realize the seam is small, directly after the process of welding, mostly used in the furniture industry.

4 Bevel Cutting Lap

The bevel cutting head realizes ±45 degree swing cutting, and the splicing is tight and seamless to ensure the subsequent welding precision.