Laser find focus summary

Laser in every contact with new equipment, or new experiments, the first step must be to focus, only to find their own focal plane, in order to correctly determine other process parameters such as the amount of out-of-focus, power, speed, etc., to do a good job. In the field debugging, the first thing is also the focus, if the focus is not right, directly leading to subsequent defects, the direction of improvement can not be discussed, and even to the wrong direction, so find the focal plane is the process of debugging, sampling, experiments, the first thing to do.

Focusing principle is as follows:

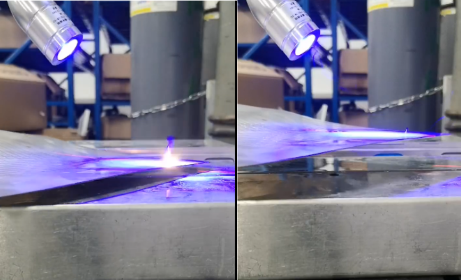

First of all, the laser beam energy is not uniformly distributed, due to the focusing mirror left and right, showing an hourglass shape, in the position of the bundle waist, the most concentrated energy, the strongest, that is, the focal point is located in the plane position. As shown in Figure 1 and 2, the depth of focus of laser beams of different energies are characterized by different, while the vibrating mirror and single-mode and multimode lasers are also different, mainly in the spatial distribution of the ability to some of the more compact, some of the more elongated (Rayleigh lengths are different), but the energy are symmetrically distributed around the focal position.

So find the focus of the basis lies in the perception of energy changes, generally with a small power, 200-500W or so, through a certain way, in the direction of the laser to find a symmetrical distribution of two welding phenomena (acousto-optic) position coordinates, to find a median, that is, the focal plane position, as shown in the figure: the material surface of the laser unit energy density is extremely sensitive, once below a certain threshold on the There will be no response. This is simple, we only need to find in the direction of the laser as shown in Figure 1, 2 two positions, in the same position from the focus of the two directions should have the same sound, sparks, splash phenomena, in order to determine the focus in the middle of these two positions.

Waveform setting:

1, welding mode select QCW mode.

2, the maximum power is set to 0.3 or so, do not set the power is too large.

3, waveform pulse width set to the first 0.1 ms, power 100%, the second 2.5 ms, power 100%. Pulse width can not be set too long.

4, the frequency is set to 1 ~ 1.5, do not set the frequency too high.

5, start focusing

For different laser beams have different methods of focusing, in general, is divided into three steps.

The first: playing diagonal method:

1, first through the guide spot to determine the approximate range of the focal plane, looking for the brightest and smallest point of the guide spot to determine the initial experimental focus;

2, playing slash notes

(1) general use of steel plate, semiconductor 500W or less, fiber optic 300W or so can be; speed can be set 80-200mm

(2) The larger the angle of the steel plate beveled the better, try to 45-60 degrees or so, the midpoint is set in the guide spot the smallest and brightest coarse positioning focus position;

(3) Then start hitting the line, hitting the line to achieve what effect? Theoretically, the line will be symmetrically distributed in the focus of the left and right, there is a trajectory from large to small and then become large, or from small to large and then become small changes in the process;

(4) Semiconductor to find the thinnest point, the steel plate in the focus position will also be white with obvious color characteristics, can also be used as a basis for locating the focus;

(5) Secondly, the fiber try to control the back of the microtransparent, microtransparent in the focus position, indicating that the focus in the back of the microtransparent length of the mid-point, at this time the focus of the coarse positioning is complete, the use of the line of laser-assisted positioning for the next step.

3, the next step to flatten the workpiece, the line laser tuning and focus to guide the spot overlap, that is, to locate the focal point, and then the last step of the focal plane verification: that is, hit the point of the method, is also the second method

(1) by hitting the pulse point way to verify the principle: is in the focal point of the position of the splash sparks, sound characteristics are obvious, in the focal point of the upper and lower limits of a demarcation point, the sound and the splash, sparks are obviously not the same as the point, record the focal point of the upper and lower limits of the mid-point of the focal point that is the focal point.

(2) and then adjust the line laser coincidence, the focus of both positioning is complete, the error is within 0.5mm. Be sure to repeat the experimental positioning, improve accuracy, to avoid the systematic errors caused by a single time.

(3)Hit the point method is also divided into a variety of different manufacturers will have different habits: applicable to a greater depth of focus, spot size in the direction of the Z-axis changes in the fiber laser, by hitting a row of points, look at the steel surface of the point of the trend, each time the adjustment of the Z-axis change of 0.5mm, hit the imprint on the steel plate from large to small, and then from small to large process, the smallest point that is the focus.

Some by hitting the point on the photo paper, generally with low power, look at the size of the ablation point of the photo paper to determine the focus, ablation point from large to small and then large, the smallest that is the focus, the error is relatively large, generally in the 0.5-1mm or so;