With the arrival of high temperature in summer, many laser cutting machines will generate a lot of heat when working, which will cause some malfunctions. So when using laser cutting machine in summer, pay attention to the equipment to do a good job of cooling preparation. High-temperature conditions, people will heat stroke, machinery is no exception, to the laser cutting machine to do a good job of heat stroke prevention and maintenance, in order to extend the service life of the equipment.

Water cooling equipment

Water cooler is a necessary cooling equipment for laser cutting machine, in a high temperature environment, the deterioration of the coolant is very fast, it is recommended to use distilled water and pure water as a coolant. In the process of use, it is necessary to regularly clean the laser and the water scale attached to the pipeline, so as to avoid the accumulation of scale leading to the blockage of the coolant to affect the cooling of the laser cooling. Coolant water temperature should not be too big a difference with the room temperature, so as to avoid the temperature difference is too large to produce condensation, with the gradual increase in temperature in the summer, laser cutting machine cooling system pressure increases dramatically, it is recommended to check the maintenance of the internal pressure of the cooling machine before the advent of high temperature, adjusted to adapt to the high-temperature weather.

Lubrication

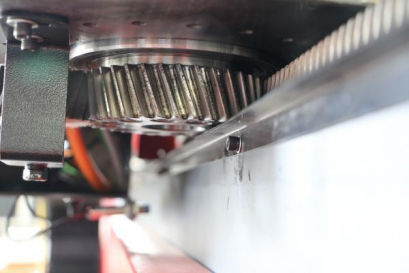

The transmission parts need to be frequently wiped dust, to ensure that the equipment is clean and tidy, so that the equipment runs more smoothly, guide rails and gears need to be filled with lubricant, filling time interval should be adjusted, compared with the spring and fall seasons should be shortened by a factor of about one, and often observe the oil quality situation. For machinery working in high-temperature areas, properly increase the viscosity level of the oil, grease oil temperature is easy to change, should be properly refueled to ensure lubrication without debris. Carefully check the laser cutting machine cutting table as well as the straightness of the track and the verticality of the machine, found abnormal timely maintenance debugging.

Line check

Check and replace the aging wires, plugs, hoses and connectors. Check whether the electrical components connector pin wire head is loose, tighten in time to avoid poor contact caused by electrical burnout and signal transmission instability.

Equipment in use have a certain loss, especially in the high temperature summer time, protect the laser cutting machine, always in good condition, in order to bring greater benefits for themselves.