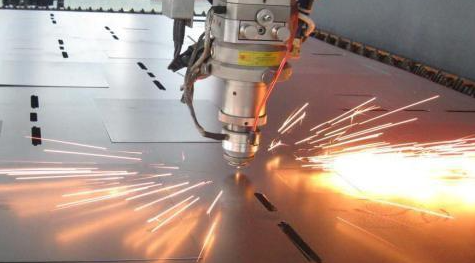

In the early application of fiber laser cutting machine, the functionality is limited, focusing can only be manually focused, there is no automatic focusing function. Manual focusing has certain requirements on the technical level of the operator, and a slight mistake in the operation will affect the accuracy and production efficiency of the product.

With the continuous improvement of production demand, laser technology has gradually matured, the advent of new laser head, changed the traditional manual focusing mode, automatic focusing successfully replaced the traditional focusing mode, the new automatic focusing cutting head has been widely used.

The perforation focus of the cutting head with manual focusing can not be adjusted, the perforation focus is consistent with the cutting focus, and the energy is insufficient and the perforation speed is slow when the thick plate is perforated. The automatic focusing cutting head can automatically adjust the focus during perforation, adjust the focus size during perforation, improve the perforation energy, and improve the perforation speed when the thick plate is perforated.

From the point of view of punching time, the speed of automatic focusing is half that of manual focusing, and the cutting effect is basically the same. However, autofocus will reduce the phenomenon of sheet overmelting caused by the short overheating time of the material, and the advantages of autofocus are obvious, which can significantly improve production efficiency and greatly reduce the perforation time of cutting thick plate materials. When different materials and workpieces of different thicknesses can be processed, the machine can also quickly adjust the focus to the appropriate position.

Therefore, the automatic focusing fiber laser cutting machine is ahead of manual focusing in most aspects, with the progress of science and technology, the automatic focusing laser cutting machine will be more practical, the processing effect is more perfect, and provide better help for laser cutting.